Although adhesive glue can be used for all purposes, it is important to note that different kinds of glues with different formulations are what make the bonds possible depending on the kind of material you need to bind. For example, you cannot use the same dendrite adhesive for leather and for metal. Rather, for stronger bonds for materials such as metal, glass, ceramic and wood, you will need to use a strong adhesive.

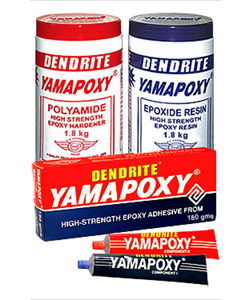

For best results, a two component adhesive can be used to join such materials together in order to create rigid adhesive bonds. The Yamapoxy, Epoxy / PolyAnde is a two component resin and hardener which helps create the strongest bonds between particles that are generally heavy and durable. The resin has an epoxy base which is translucent and the hardener has a polyamide base which is a yellowish liquid like substance.

The surface on which the bonds need to be created must be free from dirt and contamination. If the substrate is a metal, then It needs to be blasted or abraded. If the material is rubber, then it needs to be dipped for five minutes in concentrated sulphuric acid and then dried before the application of the two part adhesive. The two components need to mixed by a ratio of 1:1 by volume and then it can be applied on the surfaces that need joining with a spatula. The substrates then need to be positioned for bonding and clamped together. The final strength of the bond can be seen after 24 hours.

After partial use, the lid needs to be immediately replaced. To ensure that the products last for a long time, they should be stored in a cool and dry place away from sunlight. Since the epoxy mixed with hardener has a limited pot life, in order to avoid wastage, remember to only mix the amount required.